Lithium Battery Spot Welding Machine18650 Spot Welder

Product Features

● The programming interface is easy to operate. It supports CAD mapping, array and manual mode. Any group of programmable files can be stored.

● With welding parameter monitoring system, it can monitor welding parameters in real time.

● Adjustable single spot welding, two-spot welding, three spot welding, and the distance between two-point welding and three spot welding is adjustable.

● Custom welding head, suitable for all kinds of special-shaped batteries, as well as pure nickel welding, effectively solve the problem of sticking needle.

● Support double position welding mode.

● All parameters of equipment welding can be traced back and easy to manage data.

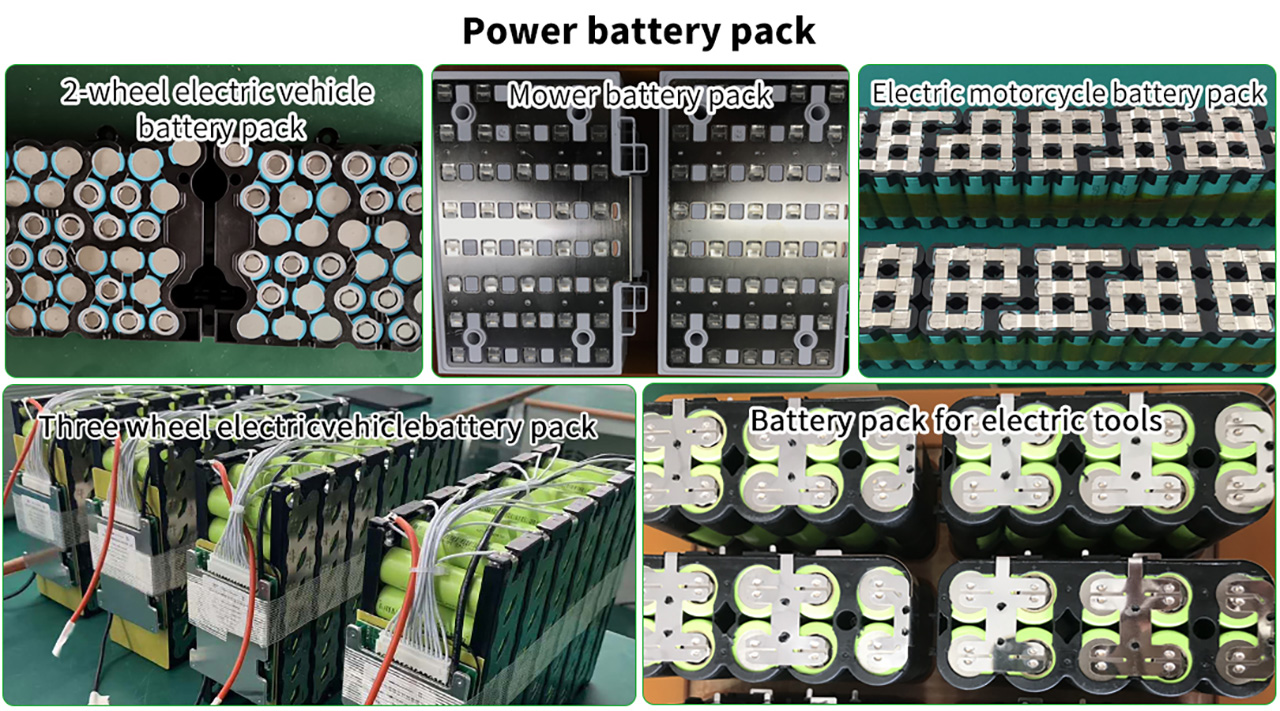

Application Areas

Operation requirements and daily use precautions of battery spot welding machine

Operational requirements of Battery spot welder

Ensure that the workpiece is placed firmly during welding.

During spot welding, the fixed electrode should be perpendicular to the workpiece, and asymmetric electrode heads should not be used in production.

In production, avoid the contact between the electrode or the surrounding surface of the electrode seat and the workpiece, so as to avoid shunt and reduce the quality of spot welding.

Spot welder is used to weld low carbon steel, stainless steel and some non-ferrous metals, and can realize projection welding between plates, as well as projection welding of nuts and studs.

Spot welding machine is an indispensable equipment for welding parts in the fields of cars, home appliance manufacturing, metal cabinets and so on.Welding quality and function need not be questioned. The new structural design is considerate in operation, maintenance and environmental protection.The direct pressure mechanism has good follow-up function, fast welding speed, low conflicting materials in the guide part, and the electromagnetic air valve is directly connected with the cylinder to speed up the action response speed, improve the dotting speed, and reduce the loss of air activity.Long service life, low noise, and pressure speed regulation function.The up and down speed of the indenter can be adjusted at will, which reduces the impact when pressurizing the welded object.

Precautions for daily use of battery spot welding machine

Pay attention to the daily patrol operation of spot welding machine. Employees must have a full-time equipment monitor, similar to the safety administrator of the enterprise.Such personnel have a certain understanding of spot welding equipment, can judge whether the equipment operates normally, and have a certain sensitivity to potential problems. Spot welding machines cannot be neglected in daily patrol operations. Wire harness spot welder

Pay attention to the technical support of the spot welding machine and make all preparations. The spot welding machine production line must have sufficient technical support.Since technology cannot be replaced by anything, and as a skilled worker, it must also be taken into account in the promotion of equipment and procedures, not all hardware promotions are suitable for the current situation of the enterprise.

Pay attention to the working environment around the spot welding machine

Resistivity is an important functional index of spot welding machine. Resistivity depends not only on the type of metal, but also on the heat treatment shape, processing method and temperature of metal.Spot welding machine has large instantaneous current, which is suitable for high current projection welding industry. It is well used in energy storage welding machines in various countries, because it has incomparable application advantages compared with other equipment.Moreover, the spot welder supervisor should not only pay attention to the operation and hardware problems of the equipment, but also check whether the operation is proper. Sometimes, if the operation is improper, the equipment may be damaged.

In general, the daily protection of spot welding machine should pay attention to the technical support of spot welding machine, and pay attention to the working environment of spot welding machine.Cheap spot welding machines regulate the materials used in the logistics distribution of the assembly line. Generally, in terms of ingredients, the production line has special rhythm and dynamic characteristics. Under long-term overload operation, machinery and equipment even increase the unnecessary workload of operators.Lithium battery automatic spot welder

- Previous: 110V 600A Lithium Battery Pack Multifunction Comprehensive Tester

- Next: Lithium Battery Welder 20000RF